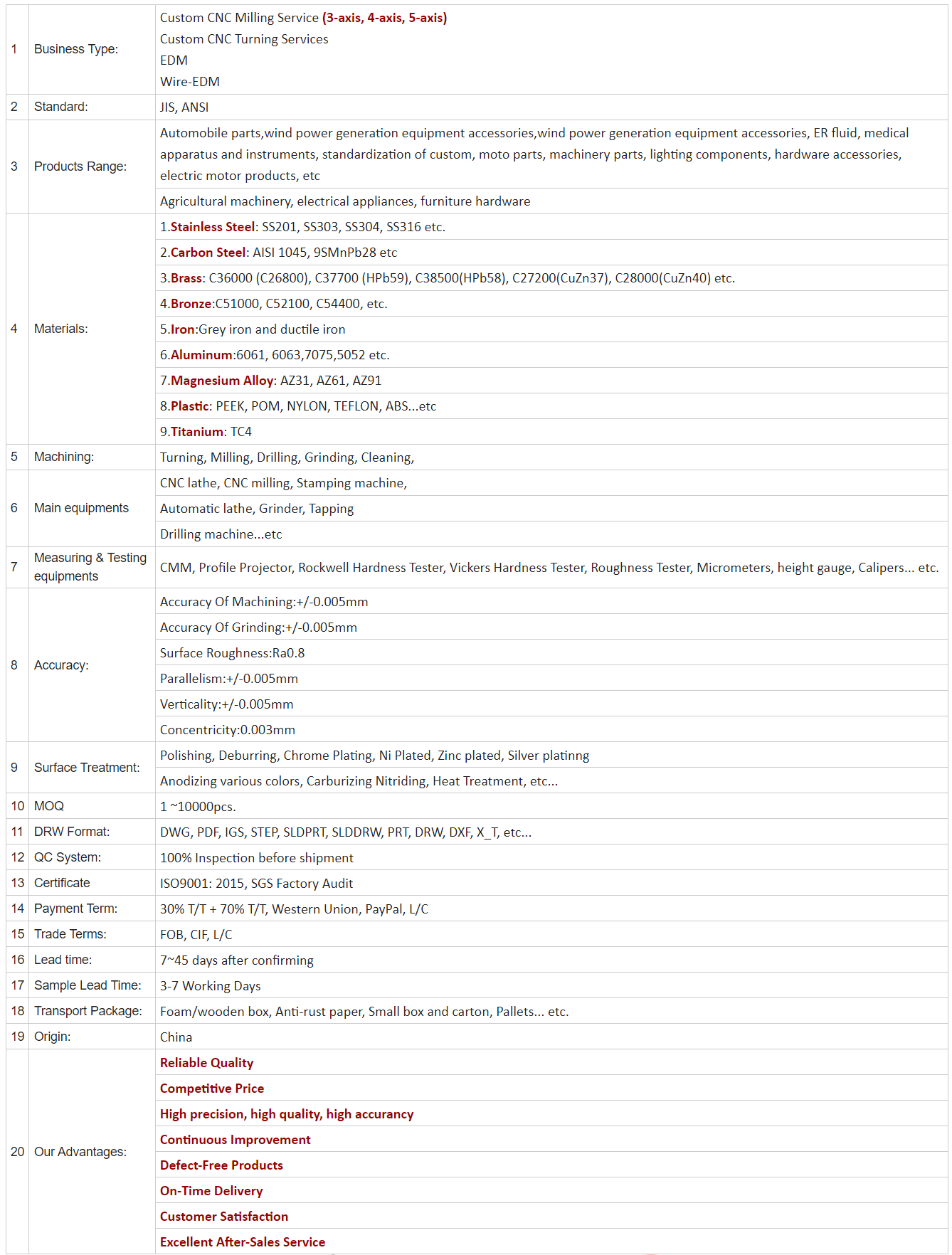

Basic Information PARAMETERS

Size: 30X60X80mm

Material: 3.3547

Hardness:

Function: For injection mold demolding

Documentation: Inspection report, Material certificate

Process tolerance: +/-0.01mm

Manufacturing Lead time: 10 Days

Transportation lead time: 3 Days (to Germany)

In today’s competitive manufacturing environment, the demand for CNC parts is growing faster than ever. From automotive to aerospace, medical devices, and consumer electronics, companies rely on precision CNC parts for accuracy, durability, and efficiency. If you are seeking a reliable CNC parts manufacturer with extensive experience, you’ve come to the right place.

Our company delivers high-accuracy CNC parts that meet the most demanding global standards. With decades of hands-on experience, advanced machining technology, and a global supply network, we provide precision machining solutions that help businesses reduce lead times, cut costs, and maintain superior product quality.

CNC parts are components manufactured using Computer Numerical Control (CNC) machining. This subtractive process transforms raw materials into precise parts using computer-controlled tools. Key benefits of CNC parts include:

High Precision – Ideal for industries requiring tight tolerances.

Consistency – Every part matches exact design specifications.

Versatility – Can be made from metals, plastics, or composites.

Scalability – Efficient from prototyping to mass production.

Whether you need custom CNC parts for a complex aerospace assembly or simple plastic components for automation equipment, CNC machining guarantees reliability and repeatability.

Off-the-shelf components often cannot meet the unique requirements of modern industries. Custom CNC parts provide:

Tailored to your CAD designs and specifications.

Reduces assembly defects and improves product performance.

Metals: Stainless steel, aluminum, titanium, brass

Plastics: PEEK, ABS, Nylon, Delrin

Materials selected for durability and cost-effectiveness

High-strength CNC parts extend equipment life.

Precision machining ensures efficiency and consistency.

Custom CNC parts enable innovation and unique product features.

CNC parts are essential across many industries:

Engine components, transmission parts, and brake systems rely on high-precision CNC parts.

Enhances performance, safety, and fuel efficiency.

Aircraft components, turbine parts, and satellite housings require high-tolerance CNC parts.

Lightweight, durable materials ensure reliability under extreme conditions.

Surgical instruments, implants, and diagnostic devices need custom CNC parts under strict compliance.

High biocompatibility and flawless finishes are mandatory.

Smartphones, laptops, and appliances depend on CNC machined parts for internal precision components.

Supports prototyping and mass production.

Robotics, assembly lines, and automated machinery require durable CNC parts.

By serving such a wide range of industries, our company demonstrates unmatched versatility in precision machining.

As a professional CNC parts manufacturer, we use state-of-the-art technology to deliver excellence:

CNC Milling – Multi-axis machines for complex geometries.

CNC Turning – Ideal for cylindrical CNC parts like shafts and pins.

Drilling & Tapping – Precision holes for assembly.

Surface Finishing – Polishing, anodizing, plating, and coating for durability and appearance.

Inspection & Quality Control – Advanced CMM ensures every part meets specifications.

Our workshop maintains tolerances as tight as ±0.005mm, ensuring precise and reliable CNC parts.

Experience & Expertise – Decades of machining experience with skilled engineers.

Quality Assurance – Strict inspections; certified raw materials.

Fast Lead Times – Optimized production for prototypes and bulk production.

Global Supply Chain – Worldwide delivery with reliable logistics.

Competitive Pricing – Affordable solutions without sacrificing quality.

Materials selection is crucial for custom CNC parts:

Metals: Aluminum, stainless steel, titanium, brass, copper, mild steel

Plastics: ABS, Nylon, PEEK, Acrylic, Polycarbonate, Delrin

Composites: Carbon fiber, fiberglass

We assist customers in choosing the best material based on performance, application, and cost.

Ordering CNC parts is simple:

Send Your Drawings – CAD files or 2D/3D models accepted.

Get a Free Quote – We provide competitive pricing.

Prototype & Approval – Sample production for testing.

Mass Production – Once approved, high-volume CNC parts are produced with precision.

Worldwide Delivery – Secure packaging and reliable logistics ensure safe arrival.

Global demand for CNC parts rises due to:

Growing need for automation and efficiency

Advances in materials and machining technologies

Increased demand for customization across all industries

Partnering with a trusted CNC parts manufacturer ensures businesses remain innovative and competitive.

When sourcing CNC parts, experience, precision, and global reach matter. Our team delivers custom CNC parts that meet strict standards while offering flexibility in design, materials, and production volume.

With fast turnaround times, professional engineering support, and proven quality control, we are your trusted partner for all precision machining solutions.

Contact us today for a free quote and discover how our expertise can drive your business forward.

Contact: Mr.Tom

Phone: 86-13450006708

E-mail: info@jiatori.com

Whatsapp:8613450006708

Add: No. 769, Jienan Road, Humen Town, Dongguan, Guangdong, China

We chat